The Challenge

With petrol and diesel engines making up 73% of transport-related pollution switching to electric vehicles is key to driving the decarbonisation of road transport and mitigating one of the main contributors to our warming climate.

A key element of this transition is energy storage and the capture of energy that can be harnessed at another point in time.

To date lithium-ion batteries have enabled the switch to electric vehicles and the portable electronics revolution, with other applications continuing to grow, including “behind-the-meter” residential energy storage systems and integration with the grid.

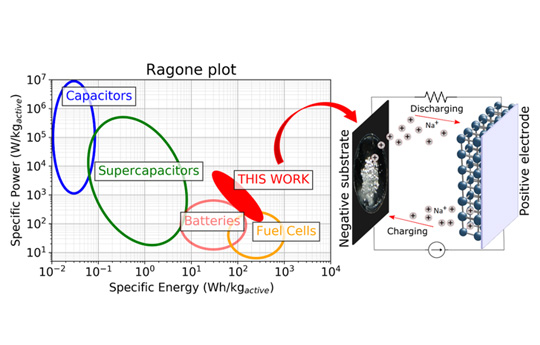

The diversity of applications of energy storage requires purpose-built batteries to achieve a specific set of performances including energy and power density, charge-discharge times, cost, life-time and safety.

The challenge is to develop new approaches to materials, chemistries, and manufacturing processes which will drive the sustainable production of batteries that are geared for specific demands.

The increasing demand for versatile, sustainable, durable, recyclable and highly performing batteries poses enormous challenges that can only be solved through a multidisciplinary effort from the engineering and science community.

Professor Serena Margadonna leads the CAPTURE centre (Circular Applications to Utilise and Retain Energy), a newly-created centre of excellence that is dedicated to the sustainable manufacturing and recycling of batteries, where all components (materials, manufacturing processes and management) are conceptualised, designed, modelled and developed within a circular economy framework.

CAPTURE (Circular Applications to Utilise and Retain Energy), is currently involved in projects focused on different energy storage technologies (sodium and lithium-based batteries and supercapacitors) which are being optimised for specific applications such as the automotive and residential markets. The focus is on upscaling production whilst also limiting the environmental impact of manufacturing and enabling the recovery and reuse of valuable materials.

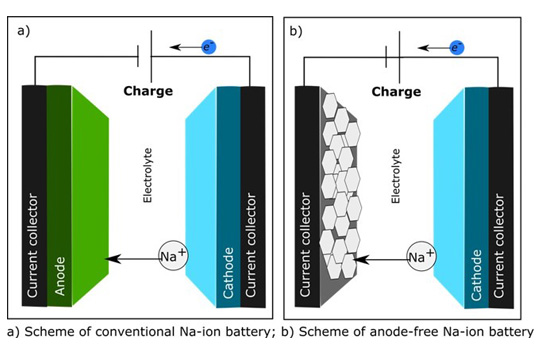

An example of this approach is Professor Margadonna’s work on Sodium ion batteries where she has re-designed the battery architecture by employing the “anode-free” concept. In this, the active storage material at the negative side is removed, and only a substrate is used to deposit sodium metal during charge and then removed during discharge.

This technology enables high-power and high energy densities, increased life-time, tunable charge-discharge times whilst also simplifying the manufacturing process and drastically reducing the materials and resources required.

Through the sodium-ion anode-free concept, Professor Margadonna and her team have demonstrated that engineering the architecture of a battery plays a vital role in expanding the range of possible applications. This is a fundamental step towards meeting emission reductions and targets for the electrification of transport.

Professor Margadonna is currently working in collaboration with ENSERV POWER to scale-up the concept for commercialisation, with the ambition of revolutionising the adoption of sustainable energy storage systems within the residential market.

CAPTURE and ENSERV POWER have been working closely to establish a joint R&D programme ReCharge+, with workstreams focusing on the manufacturing of ultracapacitors, Sodium-Ion batteries, solid-state electrolytes and Lithium-Sulphur batteries.