Optimisation of Metal Powder Particle Size Distribution from Wall Colmonoy’s Gas

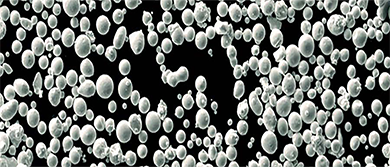

Wall Colmonoy is a globally leading materials engineering group manufacturing Colmonoy® surfacing and Nicrobraz® brazing products, precision castings, coatings, and engineered components across aerospace, automotive, glass container, oil and gas, mining, energy and other industrial sectors. An important activity is the production of fine metal alloy powders used in surface coating and brazing. Determination and control of the metal powder Particle Size Distribution (PSD) is an engineering challenge due to the complex multi-physics phenomena involved in the atomisation of the molten alloy by high velocity gas jets.

The collaboration with ASTUTE sought to achieve a better understanding of the physics of gas atomisation and the relationship between process conditions and metal powder PSD.

Solution

Wall Colmonoy conducted planned process runs to capture the data needed to determine the relationship between process conditions and PSD. Together with ASTUTE 2020+, they undertook a thorough review of the operational Gas Atomisation process focusing specifically on the gas extraction system that was in place. Modification suggestions were made to improve control over the atomisation process conditions.

Computational Fluid Dynamics (CFD)

ASTUTE 2020 used computational fluid dynamics to simulate the flow field of gas and molten alloy inside the atomization chamber and the formation of metal particulates. A three-dimensional model captured important flow features such as the near field jet expansion caused by high-speed gas jets, and the flow reversal that causes satellite particle formation. Furthermore, the CFD analysis showed the effect of different exhaust pressures and exhaust port locations.

Primary particle breakdown could not be accounted for using the available computational resources, but the secondary break-down was modelled using the Kelvin–Helmholtz Rayleigh-Transport model. Reasonable agreement with production PSD data was achieved.

Wall Colmonoy undertook experimental work to implement the research recommendations into their process. They conducted test runs of focusing on process conditions and nozzle geometry, and fed the performance of the suggested modifications back to ASTUTE.

Insights from Machine Learning

Based on the initial dataset provided by Wall Colmonoy, ASTUTE also developed the Wall Colmonoy Machine Learning Tool (WCMLT) – an artificial-intelligence-based software able to assist our industrial partner in predicting the PSD from the gas atomisation process without running additional experiments.

The predictions rely on a machine learning model based on the PSD data collected in previous batches and extrapolates/interpolates that knowledge for new scenarios.

This approach is a modern alternative to rule-based systems and can be applied to virtually any kind of dataset.

Impact

The collaborative project between Wall Colmonoy Limited and ASTUTE 2020+ has enabled the company to progress in their research and development.

Relationships between the atomisation process conditions and the achieved particle size distribution of alloy powders have been established and clarified.

The CFD simulations allowed Wall Colmonoy to optimise the atomisation tower geometry, improving the stability of the atomising process and the morphology of the powers produced.

The WCMLT machine learning tool achieved a median percentage error of 6% for the particle size distribution prediction. For such a complex process, this accuracy is attractive as it allows the company to better understand and quickly predict the relationship between process conditions and product.