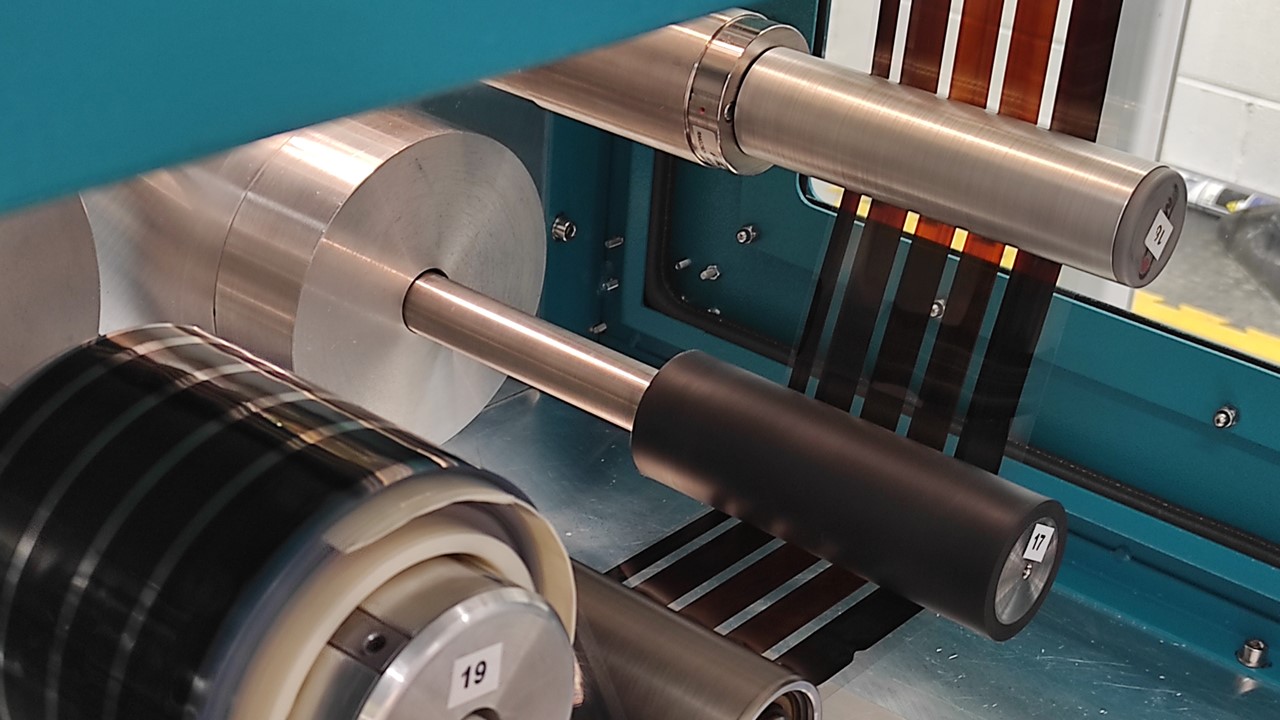

Picture: Power Roll Ltd

Swansea University experts are teaming up with Power Roll Ltd, a leading technology disruptor in the flexible PV market, for a new collaborative project to appraise novel characterisation techniques for perovskite solar cells (PSCs).

The initiative, AI-Enhanced Perovskite Manufacturing using Inline Metrology, Performance Assessment and Characterisation Techniques (AI-IMPACT), has won Innovate UK funding following a Developing Semiconductor Hardware for Critical Technologies call.

AI-IMPACT aims to address major capability gaps in inline and end-of-line testing for PSCs at scale and high throughput. Without these advancements, PSC companies could face significant hurdles in achieving product accreditation.

The project will deliver new inline testing and characterisation tools specifically designed for perovskite devices in manufacturing environments, alongside the development of robust stability guidelines to support industry standards.

Power Roll Ltd is pioneering a new lightweight, flexible, perovskite solar film with a unique, patented partial back-contacted groove architecture. Power Roll’s solar film is not only disruptive in its architecture but also in its fabrication, being manufactured fully roll-to-roll. Throughout the project, the firm will supply solar film samples to support evaluation of new characterisation methods.

Swansea University’s SPECIFIC Innovation and Knowledge Centre has been adopting technologies that reduce carbon emissions, creating buildings that can generate, store and release their own heat and electricity from solar energy.

The University’s PV group is a global pioneer in roll-to-roll (R2R) perovskite solar cell manufacturing, having developed the world’s first fully printable R2R perovskite device. In AI Impact, they will undertake a series of reviews on performance standards, metrology techniques, equipment suppliers, routes to characterise large scale devices and AI pertaining to monitoring during manufacture.

Professor Trystan Watson, from the School of Engineering and Applied Sciences, said: “Quality control and metrology in R2R manufacturing of perovskite devices are becoming increasingly vital to accelerate commercialization and enable the successful market introduction of this transformative technology”

Power Roll Ltd technical manager Dave Barwick said: “This project will afford vital support for Power Roll as we work towards achieving our ambitious technology development targets, validating and accrediting a commercial product, and finalising plans for the first gigawatt-scale scale manufacturing plant in the UK – an achievement that will position the country at the forefront of next-generation solar technology.”

The National Physical Laboratory, the UK’s leading facility for independent characterisation of photovoltaic devices, will support the development of end-of-line characterisation tool prototypes, leveraging expertise in both industry standards and characterisation techniques for optoelectronic devices.

Learn more about the School of Engineering and Applied Sciences